Exploring Innovative Solutions: The Future of Automated Ice Cream Production

New dawns for ice cream in food technology. As consumers speedily move towards unusual flavors, health-consciousness, and personalized experience, the spotlight turns toward innovative production. Enter the Ice Cream Robot, which goes beyond this premise to streamline the production process coupled with a whole new level of customization that is unparalleled in traditional production. Set to redefine the way the world's favorite frozen dessert is made, it amalgamates culinary art with the latest automation technology.

In exploring the future of automated production of ice cream, we will account for some other benefits brought in by the Ice Cream Robot to the industry. From efficient production to new ideas in flavoring combinations, this novel advancement can help in addressing varied consumer taste preferences while maintaining ideal quality standards. Join us as we venture forth into the exciting opportunity placed before the Ice Cream Robot and how it is to sweeten the dessert horizon for all.

The Rise of Automation in the Food Industry

The way food gets from the field into the world has changed forever because of the rise of automation. It has made large changes into how products are manufactured, even so far as ice cream. There's no doubt that automation has made serving efficiency, consistency, and safety in food production processes, and this continues to grow. From robotic arms picking and placing ingredients to complex software systems running whole production lines, a sunrise is breaking in on precision and speed along with the benefit of automation. In ice cream manufacturing, automation is enhancing not just production techniques but also the environment for the customer. The process may now include systems that quickly and precisely manufacture custom flavors and textures, leaving little to no room for human error, so that every scoop is guaranteed to be of the best quality. This means a faster response to consumer preferences and flexible market adaptation, whether dairy alternatives or new flavor mixes. Apart from this, automation in production systems contributes to better resource management, including the reduction of waste and energy consumption. This therefore creates positive excellence not only for manufacturers but also towards the initiatives to sustain the planet in a green way. If the past is any indication, the future of ice cream production may show an artistic configuration passing through the prism of efficiency, therefore changing the way we will indulge in this ancient favorite.

Key Technologies Transforming Ice Cream Production

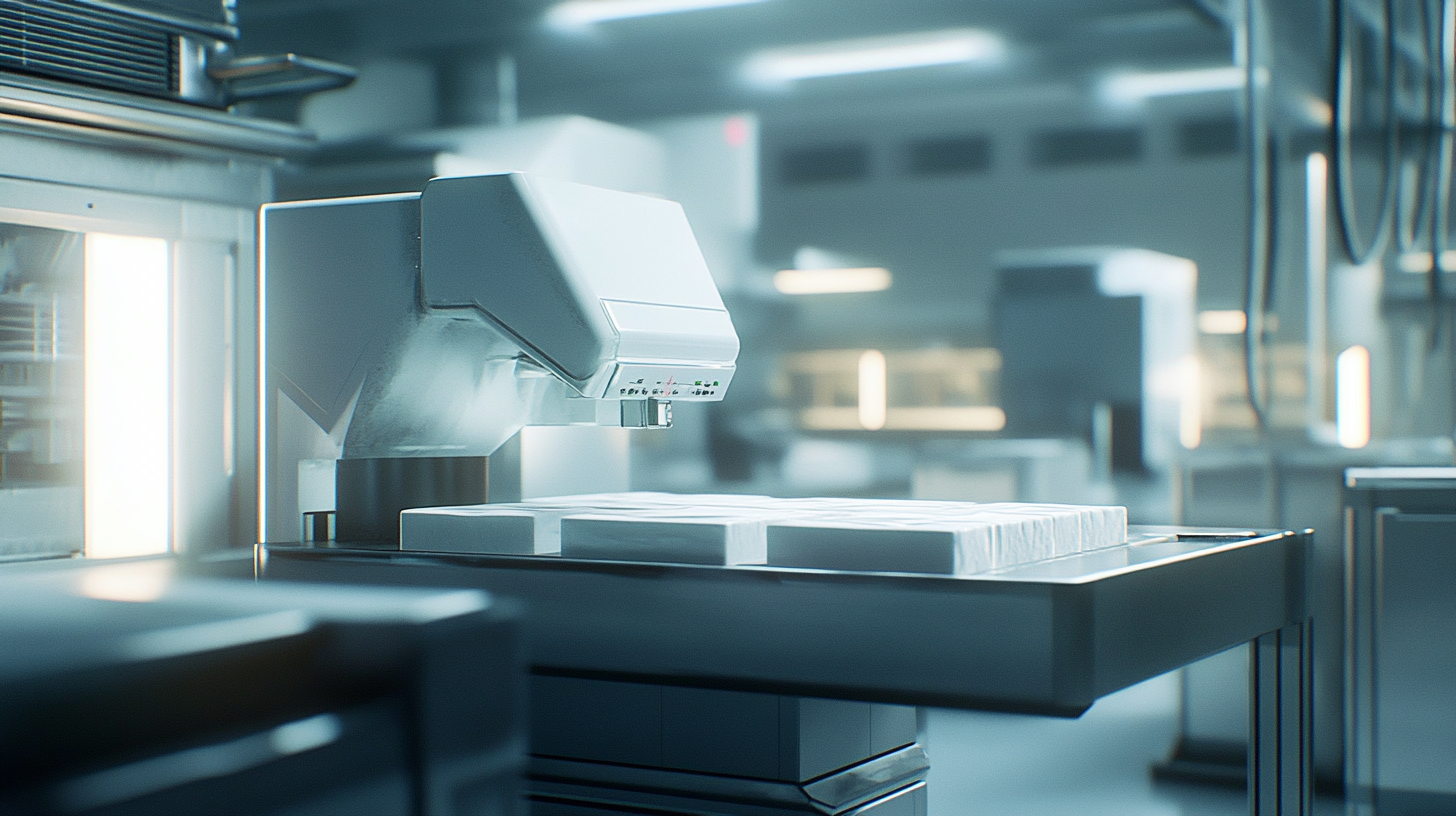

The future of ice cream production is under another massive transformative wave with innovation through the application of technologies enhancing efficiency and quality. One major development is artificial intelligence incorporation in production processes. AI algorithms may collect information about consumer preferences and calculate optimal types and recipes in a real-time manner, assisting in aligning production with market trends. This is beneficial for the production of ice cream, as it satisfies changing taste profiles and enables manufacturers to reduce waste through accurate forecasting of ingredient requirements.

Automation is another technology that is changing the way ice cream is produced. The repetitive work of mixing, freezing, and packaging is assumed by smart machines. These machines come with sensors that can ensure a consistent product every time by monitoring temperature, consistency, or any other desired parameter. Also, the use of robotics on the assembly line is increasing the speed of operations and reducing labor costs. This allows ice cream manufacturers to ramp up production while keeping quality in check.

Another great technology involves the application of blockchain to improve transparency in the supply chain. With traced ingredients from the source of supply to the final product, manufacturers can guarantee true-to-taste ice cream for the health-conscious. This very transparency builds trust, allowing brands to stand out in an already crowded market, whereby consumers increasingly seek for products aligned with their own values.

As these technologies are further refined, the future envisions that an automated ice-cream production will not only satisfy the consumer's taste preference but also enable the exploration of brand-new flavors and innovative offerings in the sumptuous realm of frozen desserts!

Sustainability Practices in Automated Ice Cream Manufacturing

There is greater demand for ice creams and, as the production of automated ice creams grows, so does the need for sustainability practices. Allied Market Research's latest report states that the global ice cream market is poised to be worth $97.4 billion by 2028, growing with a CAGR of 4.6%; therefore, now the producers are looking into different production methods which would be eco-sustainable in design and also reduce the time taken in the production cycle.

Some sustainability measures are being integrated into the automated ice cream production systems.The most exciting addition is energy-efficient equipment. International Institute of Refrigeration research indicates that energy consumption in a refrigeration plant can be reduced by more than 30% by optimizing its refrigeration system. Also, manufacturers are exploring other energy-efficient technologies such as heat recovery, which recovers waste heat generated in production processes. Heat recovery helps save energy and operational costs as well as reduce greenhouse gas emissions.

Energy-efficient practices must not sacrifice sustainable sourcing of ingredients. The Dairy Farmers of America report notes that many ice-cream manufacturers are emphasizing local sourcing and organic ingredients to decrease transportation emissions and augment local economies. By implementing automated systems with precise tracking of ingredients, manufacturers can foster transparency and accountability in their supply chains to an eco-conscious customer segment.

Thus, in essence, the future of automated ice cream production will focus on achieving some equilibrium between efficiency and sustainability. Therefore, adopting these new practices will be important for consumer acceptance and for a healthier planet.

Consumer Trends Driving Innovation in Frozen Desserts

The frozen dessert market is being led greatly by an increasing desire among consumers for different and personalized experiences. With the increase in health-aware consumers, ice cream manufacturers are being prompted to change their ways and look into making healthier options-low-calorie, vegan, or dairy-free. These products are not only directed at dietary restrictions but also offer appeal to a whole different group of consumers who are health-conscious while indulging with treats.

Talking about health trends, sustainability has taken a front seat in consumer decision-making. Preferences are starting to rise toward packaging that is environmentally friendly, production with ethically sourced ingredients, and energy-efficient production. Manufacturers are venturing into automated lines aimed at further reducing any waste and energy usage, thereby aligning with a growing breed of environmentally aware consumers. This is why automated ice cream production is moving beyond just efficiency; it is enabling the creation of a more sustainable appeal-oriented product line that resonates with that inquiry of modern buyers.

Furthermore, with the increase in customization demand has come several beneficial technologies that enable consumers to customize their frozen dessert offerings. That is revolutionizing how ice cream is produced and sold-the automated mechanisms allowing real-time changes in flavor profiles and ingredient blends based on customers' preferences. By embracing consumer-oriented trends, the future of automated ice cream production promises to be efficient and deeply engaged with the changing needs of ice cream lovers worldwide.

The Future Landscape: Challenges and Opportunities for Automation

The changes brought by automation speedily offer both challenges and opportunities for the ice cream production industry. On one hand, production automation leads to maximum enterprise efficiency and effectiveness in production. For instance, robots mix, churn, or package ice cream right from startup to finishing in minutes; thus reducing labor cost and human error. That has an impact by bettering the speed in manufacturing outlets, but ultimately scales factories according to the ever-increasing consumer demand for different tastes and specialty products.

Moving to the automated factory line, however, is not without problems. One such difficulty is the initial cost of the upgrading of existing machinery and emitting robotics into the conveyor production line. Small businesses might find it harder to argue it, especially in an unpredictable marketplace. Besides, some of the difficult and intricate processes involved in producing specific special flavors, artisanal, or unique ice creams might need an element of human creativity and touch which robots cannot replicate at this time.

But all of these risks cannot overshadow the benefits that automation brings. Most ice cream producers can put innovations in their niche instead of spending time doing some menial jobs. Quality control can also be better managed since it ensures that every batch is up to the required high standards and consumer preferences. Sure, companies will have to adopt automation; however, there will still be a need for unique branding in order to thrive in the future of ice cream production.